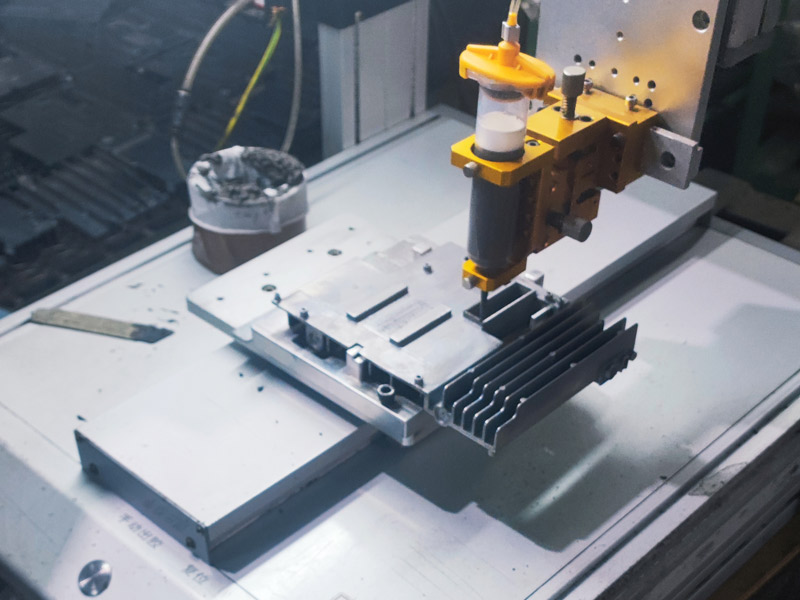

Precision wire cutting

Power Metal Group uses non-resistance and anti-electrolysis power supply. It has the functions of water immersion machining and taper cutting. The practical maximum processing efficiency is 120-150 mm2/min. The best surface roughness is ra < 0.5μm. The cutting accuracy can reach ±0.005mm。 It can be used in all kinds of mold processing, precision components, c-axis […]

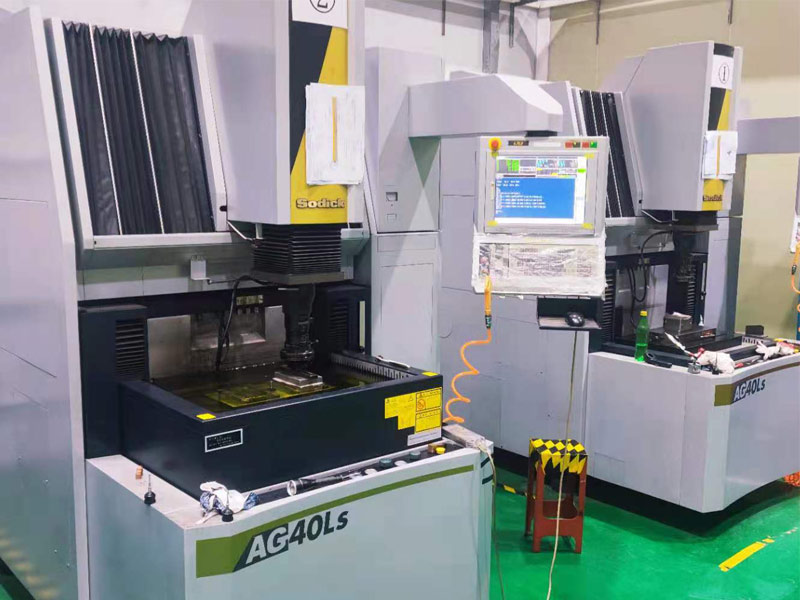

Injection molding EDM

Using the Japanese SODICK AG40Ls high-precision electric discharge machine, it can machine the molds and parts with complex shape. We can process all kinds of conductive materials, such as cemented carbide and quenched steel. Or process all kinds of marks and mirror EDM according for support customer requirements. Process characteristics and production advantages: High speed […]

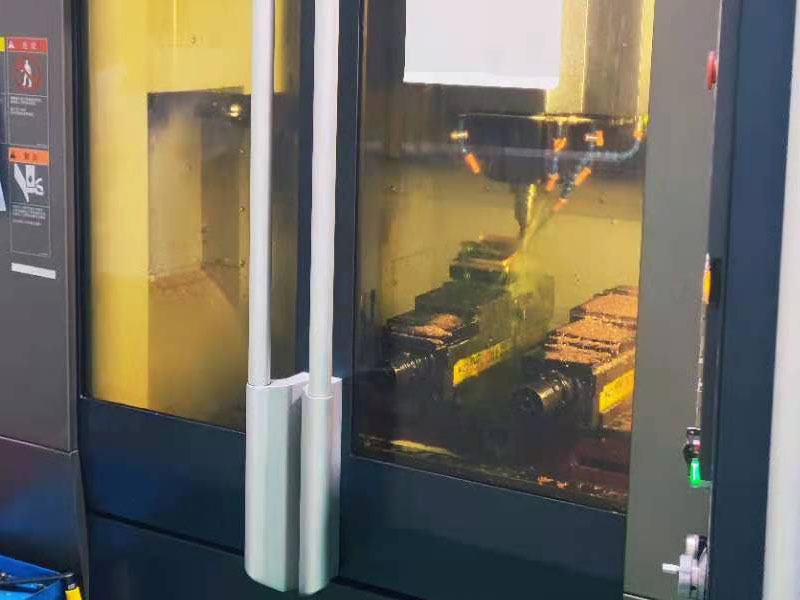

CNC machining center

Power Metal group adopts Makino F5 machining center. The maximum speed of the equipment is up to 30000 rpm and the machining accuracy is 0.0025 mm. It can process precision parts and precision 3D machining. Process characteristics and production advantages: High speed machining High precision machining Good thermal stability Strong of heavy cutting ability

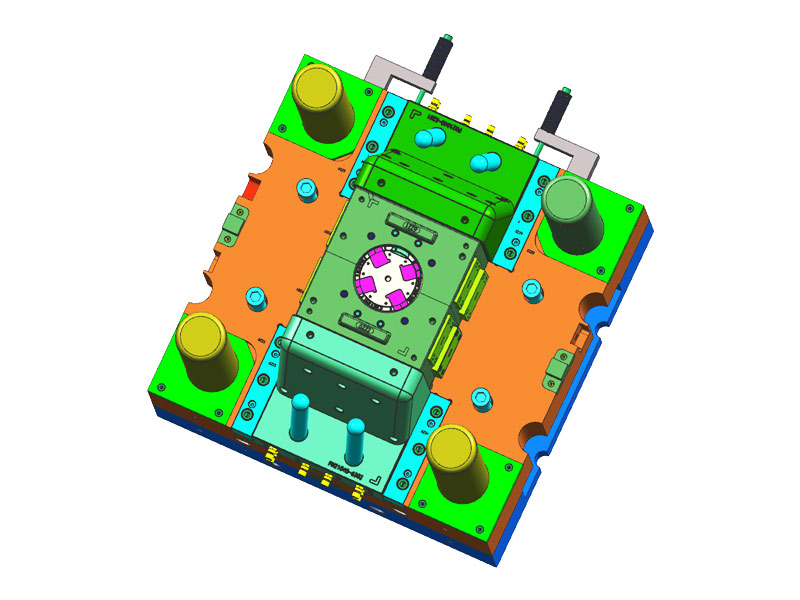

Mold design

Power Metal group has the most professional design team and advanced mold professional production experience. For sample development till mold design and manufacturing, Power Metal group has the fastest development capacity. We can develop all kinds of product molds, including medical, automotive parts, home equipment and communication electronic equipment. The Power Metal design team has […]

Assembly Processing

Power Metal group has professional technology and experience which can cooperate with customers to provide assembly service to reduce costs. And it will improve the competitiveness for company. The main post-processing as spot welding, die-casting and aluminum extrusion products special process of dispensing and dropping conducting resin and various product assembly processes.

Stamping

Power Metal group uses SEYI precision stamping machines. It can cooperate with customers to produce customized built-in parts or products with high precision requirements. Combined with injection molding product line, it can provide customers with integrated product design and provide customers with the most cost advantage of service. High speed stamping can maximize production capacity. […]

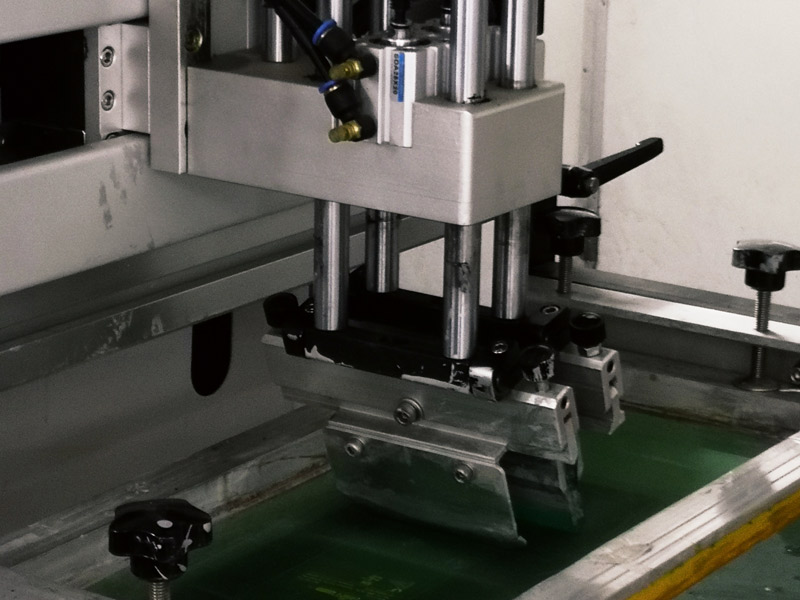

Screen printing & pad printing

Power Metal group uses the latest automatic screen printing and pad printing machines. Accumulated years of screen printing and pad printing professional technology. We support to print all kinds of high-end products. Process characteristics and production advantages: Automatic / semi-automatic screen printing and pad printing equipment Multi color synchronous pad printing Anti UV ink […]

Injection post-processing

Power Metal group has professional technology and experience which can provide customers with injection post-processing. The main post-processing include product component fusion, high gloss product lamination process, ultrasonic fusion process, high-precision logo labeling and Mylar sticking process etc.

Injection molding

Power Metal group uses Japan’s latest electric injection molding machine, PLC fully automated production, with the most professional production technology team. We can produce high-end precision injection molding products, mainly apply in the production of medical, Netcom equipment and other high-end products. Process characteristics and production advantages: High gloss injection molding High precision injection […]